![]()

|

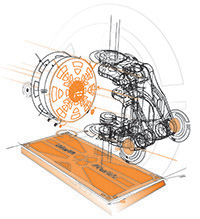

Thanks to the use of cutting-edge engineering software, we are able to quickly develop the product shape, process technology and determine the cost of implementation. 3D designing allows precise development

In order to ensure the highest quality and reliability of our products, we constantly monitor the technical parameters of the process. Our laboratory routinely carries out a number of tests associated with metallurgy and the form creation technology.

|

|

|

_____________________________________________________________________________________________

We provide comprehensive design and executive services:

• DESIGN

preparation of the foundry equipment and casting design based on

the provided documentation or detail

• EQUIPMENT

- execution of complete foundry equipment

- adaptation, optimization of the existing modeling,

- equipment repair and regeneration

• CORES

Cores are made using the following methods:

- Hot-Box

- Cold-Box (CO2, amines)