![]()

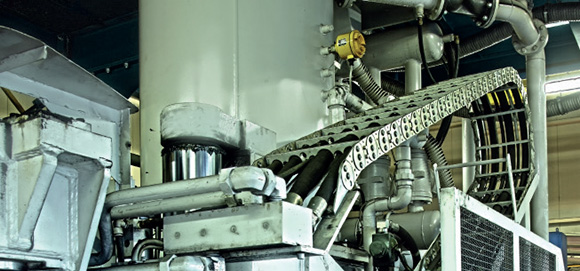

Installed in 2012 was the induction pouring furnace by OTTO-JUNKER RGD Ge 4/250 with the automated form pouring process and the iron heating and holding function. One of the innovative features of the "intelligent" pouring system is its ability to repeat (memorize and imitate) the dynamics of pouring of individual forms within the batch pouring process.

The automated form pouring machine is equipped with a feeder of the modifier which allows to carry out the iron modification process using the metal stream application technology. Operation of the feeder is controlled in a fully automated system both in terms of the modifier quantity and the time and intensity of its feeding. It ought to be noted that this modification method used by most modern iron foundries is the most effective one from the standpoint of the impact on the structure and properties of cast iron.

In addition, measured and archived by means of the integrated optical pyrometer is the pouring temperature of every form.

We specialize in the production of gray cast iron castings:

• EN-GJL-150 in acc. with PN-EN 1561 ( GG 15 in acc. with DIN 1691)

• EN-GJL-200 in acc. with PN-EN 1561 ( GG 20 in acc. with DIN 1691)

• EN-GJL-250 in acc. with PN-EN 1561 ( GG 25 in acc. with DIN 1691)

We provide comprehensive machining of castings on CNC machining centers along with the execution of measurements on measuring devices.